Create Your Custom Samurai Sword

How is the Wakizashi Made?

Like any other Nihonto, the process of creating a Wakizashi goes through a long process. For the material, these swords are made using Tamahagane, a type of traditional Japanese steel.

Tamahagane is produced via smelting process, resulting in layers of steel with different carbon concentrations. Swordsmiths perform the smelting process in a clay vessel called the Tatara.

Several modern swordsmiths still use the traditional procedure to produce Tamahagane. They do this in the last operating Tatara smelter in Yokota, located in Shimane Prefecture.

However, Tamahagane is full of impurities, so swordsmiths perform a folding technique. Before they start, they choose the suitable pieces of Tamahagane, then forge-weld this into a single block. It will then form the outer skin of the finished blade.

After that, the smith will hammer and fold the block back on itself to work out the steel’s impurities and homogenize the carbon content throughout the whole piece of metal. Only experienced swordsmiths can control the quality of steel with high accuracy using this process.

After folding the blade, the smith heats the hard high carbon steel. He shapes this into a U-shaped channel and hammers the steel.

Coating the Wakizashi is the next step. Smiths do this to keep the blade protected and to form the Hamon. It is a signature wavy design that appears due to the clay tempering process.

After coating, the swordsmith brings the Wakizashi back to the fire to heat it below 1,500 degrees Fahrenheit. Once done, they pull the Wakizashi out of the fire to quench it.

These procedures allow for the blade to bend and create its distinct curvature. It’s a tricky and challenging process, that’s why only experienced swordsmiths should do it. Out of three swords, one is lost due to damage in this process.

Polishing is another critical process in creating the Wakizashi. It takes more than two weeks for a polisher to sharpen its edge using grinding and polishing stones. These water stones are expensive, and families usually pass these down to the next generation.

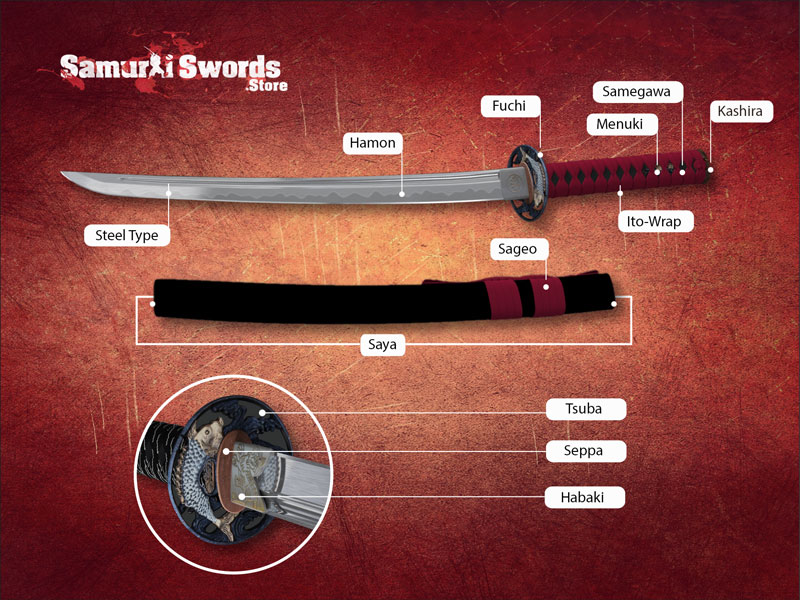

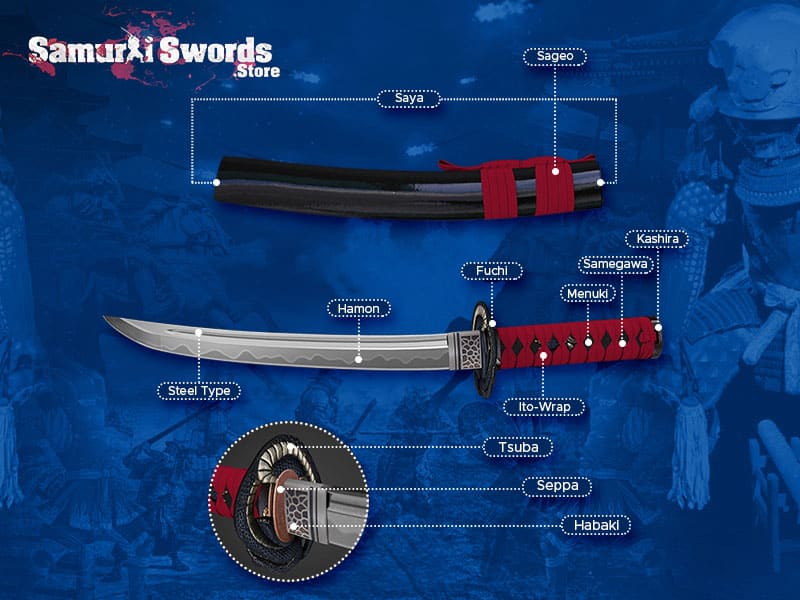

The stones for polishing and sharpening Nihonto consist of hard silicate particles suspended in clay. The final touches of the sword involve adding the Tsuka and other fittings such as the Tsuba, and other ornaments.

What’s the Best Steel for a Wakizashi?

It’s best to use carbon steel for the Wakizashi. It’s good to note that each type of steel differs in its mix of materials and elements.

The best steel type depends on the sword’s intended use. Taking a look at some of the usual steel types will make it easier to select the material for your Wakizashi blade. Some examples are solid, while others can retain their sharp edge for long periods.

For Japanese swords like the Wakizashi, carbon steel is an excellent option. It doesn’t only create a beautiful blade, but it can also hold a sharp edge and withstand the harshness of Tameshigiri.

An acceptable steel type for creating a Nihonto is 1045 carbon steel. It’s not the best steel for a Katana due to its low carbon content.

However, it’s hard enough for a functional sword. A long-lasting and more durable blade for training and combat requires steel with higher carbon content.

1060 carbon steel has a good balance between stability and toughness. It’s one of the best steel types for a Nihonto and is more commonly used compared to 1045 carbon steel.

1095 carbon steel can retain its razor-sharp edge longer than blades with lower carbon content. It has a high amount of strength, making it one of the best steel types for creating a functional Wakizashi.

Another type is 9260 spring steel, a flexible material that allows swords to return to its original form. Swords made from this material can bend up to 90 degrees without breaking. It contains 0.60% carbon and a small amount of silicon.

The best steel type for a Wakizashi is T10 steel or tool steel. This material makes strong swords with a hard edge that can retain its sharpness. It’s an excellent choice if you’re using the Wakizashi for extensive Tameshigiri.

T10 steel is well-known for its toughness and durability, making it the top choice among swordsmiths.